Services

SLS Printing

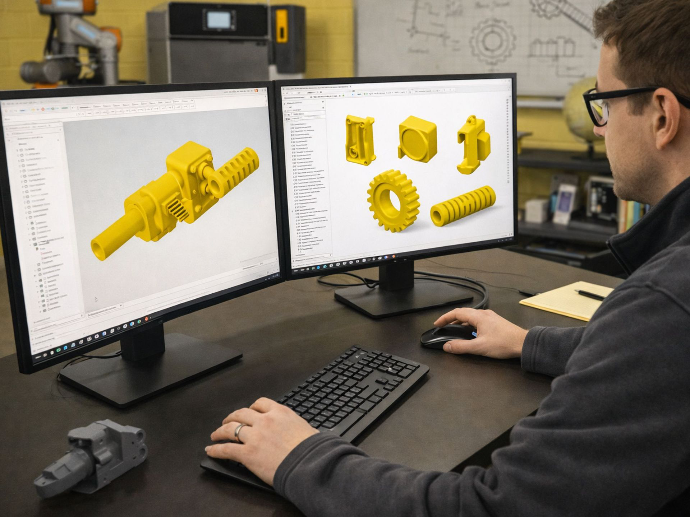

Industrial selective laser sintering (SLS) for production-grade additive parts where mechanical performance, geometric freedom, and repeatability are critical.

Lemonade Manufacturing produces SLS parts primarily in Nylon (PA12) and TPU, supporting applications that require strength, durability, and consistent material properties across batches. SLS enables complex geometry, internal features, and functional assemblies without tooling investment.

Our SLS workflows are tuned for dimensional stability, material performance, and batch-to-batch consistency, making them suitable for low- to mid-volume production—not just prototyping.

Common applications include:

End-use housings and enclosures

Functional brackets, clips, and mounts

Short-run production components

Snap-fit and interlocking assemblies

Flexible or elastomeric parts in TPU

Best used when tooling is impractical and repeatability matters.

Post-Processing

Integrated post-processing designed to make additive parts production-ready.

Lemonade Manufacturing provides structured post-processing workflows organized into defined finish tiers. Each tier is selected based on functional requirements, cosmetic expectations, and repeatability needs.

Post-processing tiers include:

Basic: Media blasted to remove powder residue and create a uniform surface texture

Intermediate: Mechanically polished to reduce surface roughness and improve visual and tactile quality

Standardized post-processing supports consistent surface quality, predictable outcomes, and repeatable results across production batches.

Best used when surface texture, appearance, or downstream finishing consistency is important.

Paint & Finish

Durable paint and coating finishes applied to additive parts for enhanced performance and professional appearance.

Lemonade Manufacturing applies oven-cured Cerakote H-Series coatings to SLS parts as part of an integrated production workflow. Finishes are selected based on part geometry, material, and intended use, with emphasis on wear resistance, color stability, and repeatable cosmetic results.

Coating operations are treated as a controlled production step—not a cosmetic afterthought—supporting consistent outcomes across batches and repeat orders.

Paint and coating finishes are commonly used for:

Consumer-facing or customer-visible components

Parts requiring abrasion or chemical resistance

Color-critical components

Assembly-ready production parts

Standard Coating Colors (Cerakote H-Series)

To support repeatability and predictable lead times, Lemonade maintains a standard, production-ready color set using Cerakote H-Series coatings.

Standard colors include:

Black (Graphite Black, H-146)

Graphite / Dark Gray (Cobalt, H-112)

Light Gray (Battleship Grey, H-213)

White (Bright White, H-140)

Lemonade Yellow (Corvette Yellow, H-144)

These colors are selected for durability, availability, and consistency across production runs.

Additional Cerakote H-Series colors are available by request and subject to review for availability, lead time, and batch consistency.

[View full Cerakote H-Series color catalog →]

Engineering Services

Engineering review services to support manufacturability and production repeatability.

Before production, we evaluate part geometry, critical tolerances, and finish requirements to identify risks that could impact quality, lead time, or consistency. This early review helps align additive manufacturing and finishing processes with real-world use and downstream assembly.

Engineering services are advisory in nature. Customers retain full ownership of all design decisions and intellectual property.

Best used when transitioning from prototype to production or introducing finished, end-use parts.

Materials & Finish Summary

Materials

Nylon (PA12): Rigid, durable, production-grade

TPU: Flexible, impact-resistant elastomer

Finish Tiers

Basic: Blasted

Intermediate: Polished

Advanced: Coated (Cerakote H-Series based systems)

Production-focused additive manufacturing

Delivered as a system.

Lemonade Manufacturing combines industrial SLS printing, structured post-processing, durable coating finishes, and engineering review into a controlled workflow designed for real use. Our services are built to support low- to mid-volume production, repeat orders, and predictable outcomes—without the cost and commitment of tooling.